Home News Industry-news Precautions for terminal block…

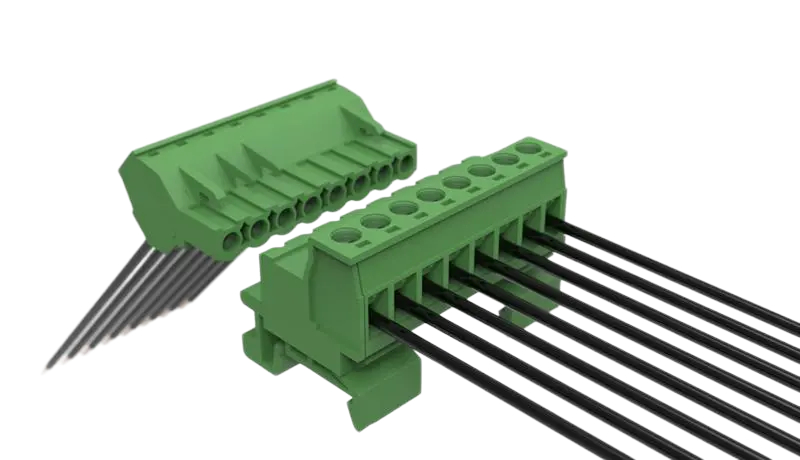

A terminal block is an accessory product used to achieve electrical connections, and is industrially divided into the category of connectors. The following are the precautions for the wiring of the terminal block.

1. The tightening wiring should be moderate in strength to prevent the bolts and nuts from being buckled with excessive force. If the bolts and nuts that have been buckled are found to be replaced in time, it is forbidden to work.

2. When tightening or loosening the screw with a screwdriver, you must force the screwdriver to tighten the screw, and then tighten or loosen it to prevent the screwdriver and screw from slipping, causing the screw damage to be difficult to disassemble, especially the common open in the hanging box.

3. Do not act recklessly to find bolts and nuts that are difficult to disassemble. To prevent deformation, it is more difficult to disassemble. Appropriate knocking or screw loosening agent, dilute hydrochloric acid, etc. should be dismantled later.

4. Do not use vise to tighten or loosen the bolt and nut to prevent damage. Adjust the opening when using a spanner to prevent the bolt and nut from being damaged and deformed, making it difficult to disassemble.

5. The same terminal block can connect up to two wires of the same type and specification.

6. For wiring terminal blocks that are easy to loose or easy to contact, the wire joint must be fastened to the terminal block with a "?" Type to increase the contact area and prevent loosening.

7. When connecting the wire joints or wire noses to each other, it is strictly prohibited to install non-copper or poorly conductive gaskets in the middle.

8. When the wire joints are connected, the contact surface must be smooth and free of oxidation. When the wiring nose or copper bar is connected, the contact surface can be cleaned and coated with conductive paste, and then tightened.

9. When connecting temporary wires, the single-lead flexible cord is required to fold the connector in half once, and then connected to the lower opening of the air opening; the single-core hard wire should be connected to the lower opening of the air opening in the form of "?".

10. 30KW and above, it is not allowed to cross the gasket with poor conductivity, such as galvanized nut, flat washer, spring washer, etc. between the motor outlet and the cable wire connecting the motor.

11. When using insulation tape to wind cables or other equipment to be protected from insulation, the insulation layer should be wound from one end to the other end at a pressure of 1/2, and at least back and forth.

The above is an introduction about the wiring precautions of the terminal block. I hope that everyone will be helpful after understanding the wiring precautions of the terminal block.

Name: Tony Huang

Mobile:+8613968045858

Email:[email protected]

Add:Room 2219, #3 Building, Xinbei Qianjiang International Plaza, Qianjiang Economic Development Area, Yuhang District, Hangzhou, Zhejiang,CN